Flint Systems Delivers World’s First Underwater Welding and Cutting Simulator to the Polish Navy

A major leap in maritime training technology: the WELES simulator now enables safe, realistic underwater welding and oxygen lance cutting for naval personnel.

business maritime economy navy ports equipment and technology tricity news14 june 2025 | 07:43 | Source: Gazeta Morska | Prepared by: Kamil Kusier | Print

fot. Flint Systems

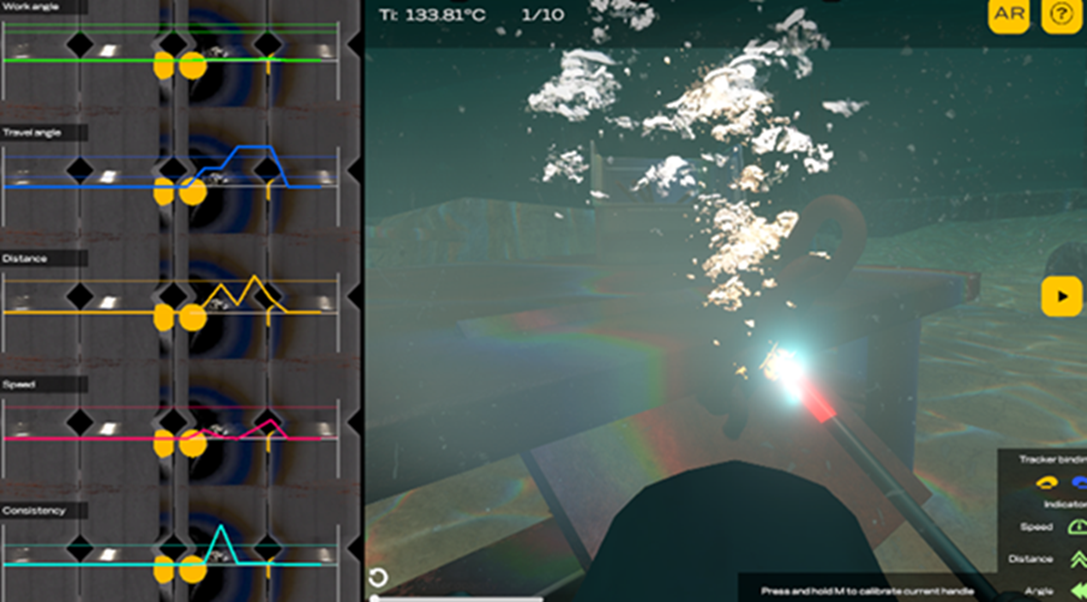

Polish technology firm Flint Systems has successfully completed the second and final phase of its contract with the Naval Port Command in Gdynia, delivering a groundbreaking upgrade to its WELES welding simulator. The latest version includes an industry-first module for underwater welding and oxygen lance cutting, developed to meet the specialized requirements of the Polish Navy.

This pioneering VR-based system replicates real-world welding conditions, now extended to include anchor chain welding and cutting under simulated underwater conditions. The final delivery, completed in May 2025, marks a significant innovation in military and maritime vocational training.

Between 2024 and 2025, Flint Systems delivered two full WELES simulator systems, supporting training in four core welding methods:

GMAW (MIG/MAG), SMAW (MMA), GTAW (TIG), and FCAW. The system enables hands-on experience with various materials – including stainless steel, mild steel, aluminum, and copper – and simulates plate thicknesses ranging from 2 to 20 mm.

Next-Generation Training for Harsh Marine Environments

Developed in close cooperation with subject-matter experts, the underwater technology module provides a realistic and fully immersive training environment using virtual reality (VR). The simulator allows naval personnel and marine industry specialists to train without risk, reduce costs, and build mission-critical competencies in a controlled setting.

- We are proud to be the first in the world to deliver a simulator for underwater welding and cutting. This not only strengthens the Polish Navy but also marks a milestone in the evolution of welding training, said Leszek Tarnawski, CEO of Flint Systems.

Key Features of the WELES Underwater Module:

- True-to-life simulation of underwater welding and anchor chain cutting scenarios

- High safety through VR training, eliminating exposure to real-world hazards

- Cost-efficiency by removing the need for consumables and physical setups

- Versatility, supporting a wide range of materials, techniques, and user profiles

The WELES simulator positions Flint Systems at the forefront of maritime and defense training innovation, offering scalable, safe, and effective solutions for navies, shipyards, and offshore industries worldwide.

Buy us a coffee, and we’ll invest in great maritime journalism! Support Gazeta Morska and help us sail forward – click here!

Kamil Kusier

redaktor naczelny

comments

Add the first comment

see also

Austal partners with Damen for local construction of LST 100 for Australian Army

The submarine contract of the decade? Canada weighs South Korea against Germany

Bechtel signs contract with Doraco for Poland’s first nuclear power plant

When two powers clash, Poland must be ready to act. Military security must be the priority

MON, Arka Gdynia and AMW sign letter of intent supporting "Green Industrial District - Kashubia" project

Mine countermeasure vessel Jaskółka begins sea acceptance trials

PEJ relocates headquarters to Pomerania. A strategic step in Poland’s nuclear power development

Radmor hosts delegation from the Republic of Turkey. Advancing maritime security cooperation

3D-printed catamaran: robotic manufacturing sets course for the future of small craft

Navantia and Fincantieri deepen cooperation on the european patrol corvette programme

ADVERTISEMENT

ADVERTISEMENT